![[Global Application Case] Türkiye Liquid Nitrogen Pipeline Project Uses HUATAO Brand Aerogel Felt To Achieve Efficient Cold Insulation](https://aerogel-blanket.com/DM-static/upload/image/cn/20250411_091022_9768.jpg)

——The measured temperature difference reaches 180 ℃! See how international customers use ultra-thin materials to solve pipeline condensation problems

1. PROJECT BACKGROUND

In April 2025, in order to upgrade the insulation system of its LNG pipeline, well-known enterprises in the liquid nitrogen transportation field in Türkiye finally selected our HT200 aerogel felt as the core cold insulation material after several rounds of technical comparison.

2. SOLUTION

Product specifications

Model: HT200 Aerogel Blanket-200C

Thickness: 10mm (saving 80% space compared to traditional materials)

Thermal conductivity: 0.021W/(m · K) @ 25 ℃

Operating temperature: -200 ℃ to 200 ℃

Construction highlights

Multi layer staggered wrapping technology ensures zero thermal bridge

Customized cutting of irregular pipe fittings, perfectly fitting complex structures

Exterior moisture-proof layer design to cope with Mediterranean climate

3. CUSTOMER VALUE

✓ Energy saving effect: reduces cooling loss by 37% compared to traditional materials

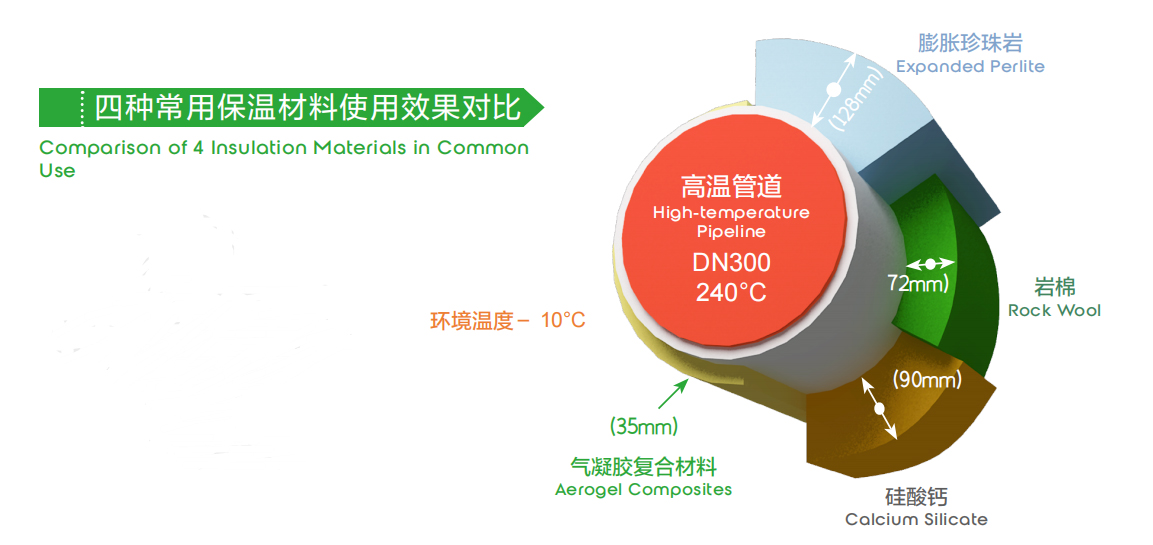

✓ Space optimization: Only 1/3 thickness is needed to achieve the same insulation effect

✓ Maintenance cost: Corrosion resistance prolongs equipment maintenance cycle

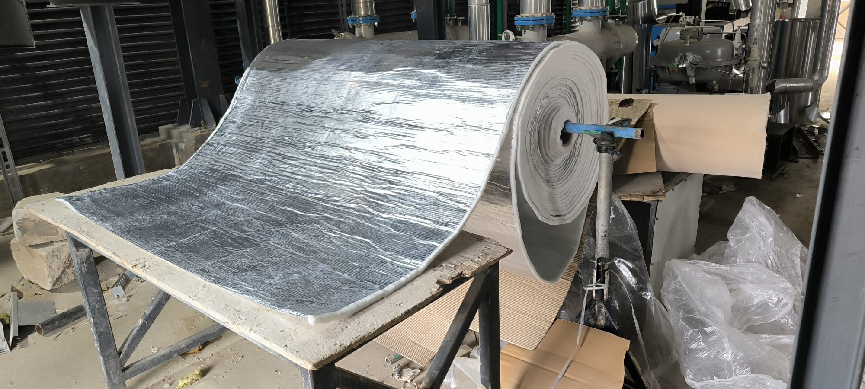

4. ON SITE FILMING

Figure 1: Technicians are installing aerogel felt

Figure 2: Panoramic view of the completed pipeline system

5. CALL TO ACTION

Does your project also face the following challenges?

Insulation requirements in high humidity environments

Design of Insulation Scheme in Limited Space

Must comply with international fire safety standards and have material ASTM testing

[Contact Now] Our engineering team for customized insulation solutions!

Contact us ↓

Annie Lu

Huatao Group

annie.lu@huataogroup.com

Mobile: 0086 18032422676 ( Whatsapp/Wechat/Viber)

https://wa.me/008618032422676

www.aerogel-blanket.com

Mainly Product

Aerogel Blanket Aerogel Insulation Sponge Aerogel Insulation Film Composite Aerogel Products Aerogel Coating Aerogel Panel Aerogel Particles and Powder

can not be empty

can not be empty